Energy from Waste (EfW)

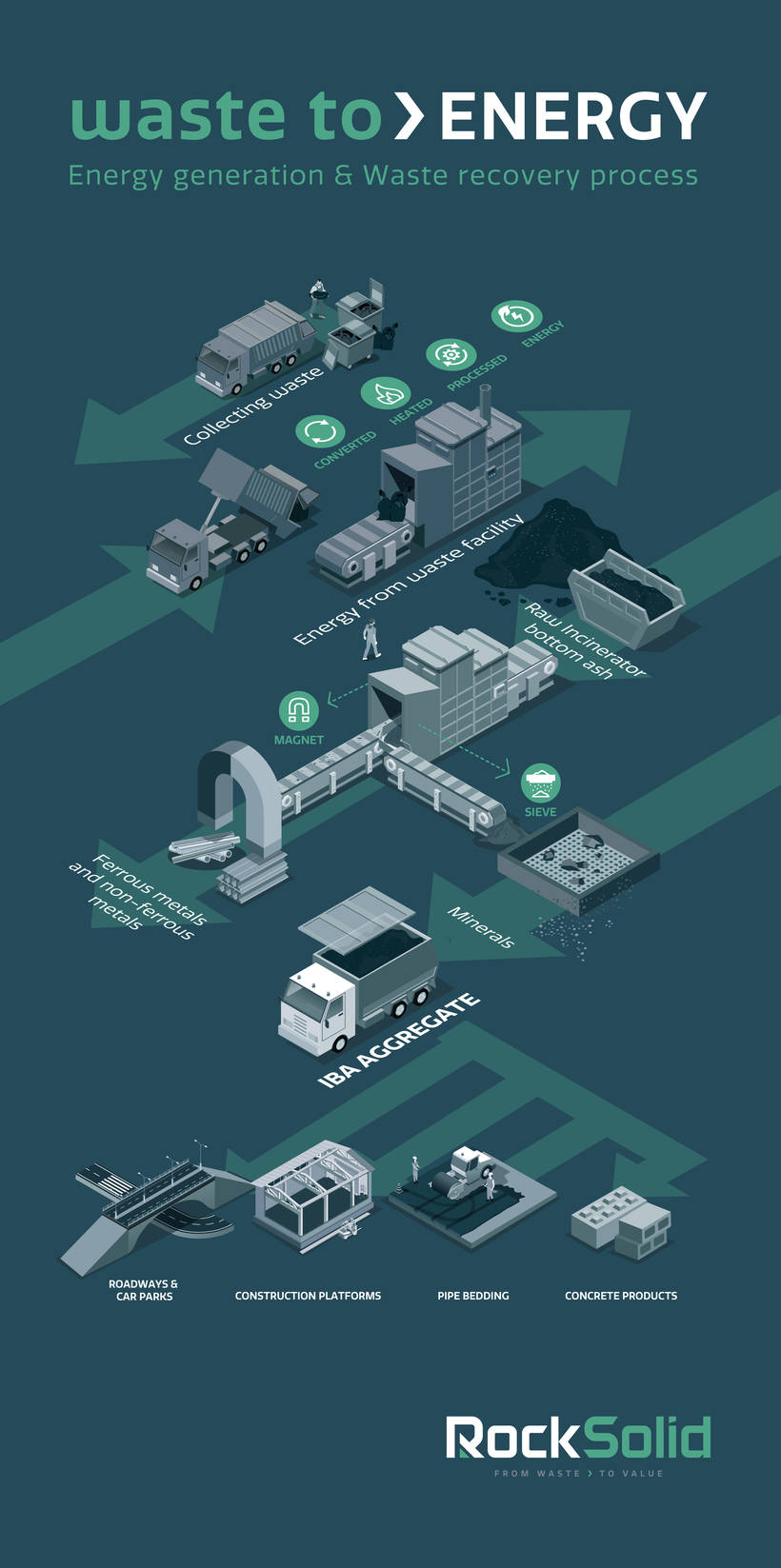

To help reduce our combined carbon footprint and to prevent waste going to landfill, non-reusable domestic waste and mixed commercial waste is now Incinerated within Energy from Waste plants (EfW) in many areas of The UK and Europe.

This strictly controlled incineration process produces valuable energy which is subsequently fed back into the National Grid or directly into local communities. The residual material which is generated from this incineration process is called Incinerator Bottom Ash or IBA.